The CPRS is comprised of nine dissimilar metals such as Copper, Zinc and Nickel, etc., which forms a special catalyst when placed in contact with fluids.The metals act as a special catalyst to enable a change in the electrostatic potential of the fluids, inhibiting the binding forces between particles in the fluids.Suspending solids and inhibiting the formation of scales, paraffin, Asphaltenes and corrosion.The metals are non-sacrificing during the reaction process.

1.Types and Functions

COMPLETE SERIES

Downhole Units

Surface Units

ONE TOOL, MULTI-FUNCTIONS

Paraffin, Asphaltenes, scale and corrosion Prevention

Paraffin, Asphaltene, scale and corrosion removal

CO2,H2S separation from the liquid

Bacteria, Algae removal and water quality improvement

2. CPRS Downhole Units

Bar Style : To be used for 2-3/8”, 2-7/8”, 3-1/2” production tubing, a 1.66” bar, with a flowrate of 90GPM

Disk Style : To be used for 2-3/8”, 2-7/8”, 3-1/2”,a string of 10 discs.Full flowrate processing of the wellbore liquid

Housed with a short standard API production tubing joint.

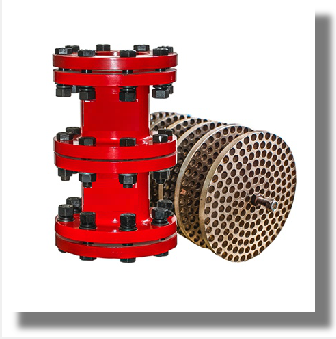

3. CPRS Surface Units

| CPRS Surface Units | Photo | |

| Canister Style |  | |

| Inline Style with Fixed Diameter |  | |

| Inline Style with Variable Diameter |  | |

Size Range: 1” to 24”Standard Pressure ratings: 2.5 MPa-25 MPa, higher pressure units can be built per the customer requests. Housing Material: Carbon Steel. Stainless Steel, depending on the applications and customer requestsThe units will come with companionflanges, and boltsTo be used for both oilfield production wells and water injection wells.

More information,please download the above PDF brochure.Thank you!